Why Use Metal Enclosures for Industrial Equipment?

Metal enclosures are available in a wide range of sturdy materials. Some of these materials are

Stainless steel, carbon steel, aluminum die cast or aluminum extruded enclosures. Having an

enclosure with a sturdy metal will offer your industrial equipment enhanced as well as excellent

safety. Metal project boxes are available that can be used outdoors and indoors for most of the

industrial applications. Several options are available based on whether you are on the lookout

for a waterproof metal box or a metal hinged box or an electrical metal enclosure. Based On

your requirements on size, shape, design and make, you can choose your ideal metal

Enclosures.

What Exactly is a Metal Enclosure?

We all are aware that metals are solid substances that have the capability to hold out against

high temperatures without getting melted and having greater resistance to stress. In industrial

environments, it is important that equipment requires metal enclosures in order to protect them

from a wide range of materials like solvents, gasoline, hydraulic fluids and alcohol and much

more.The electroconductive nature of metals help in highly sensitive applications like

electromagnetic interference or EMI. Another main reason why metal enclosures are preferred

in industrial applications is its protective feature from pollutants and outside noise. When it

comes to heat absorption, non-metal enclosures are not a good choice because of their poor

conductivity. Hence metallic enclosures are most preferred where there is a requirement for

holding heat inside the enclosure. Another setting where metallic enclosures offer great benefit

is on a Radio Frequency (RF) setting as they show a better defensive quality. The metal

enclosure has the power to act as a barrier against RF radiation.

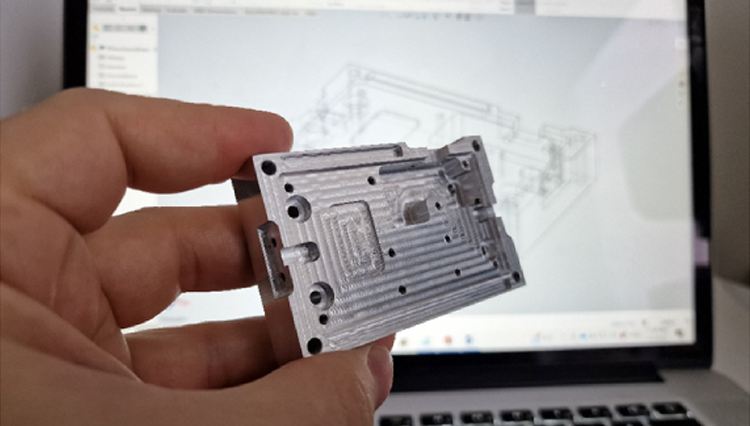

How to Make a Metal Enclosure?

Sheet metal enclosures are made by bending and sealing the sheet metal.

It’s important to always assess the strength of the material. The flexibility of the sheet metal

is assessed based on its thickness, chemical composition and surface conditions. Usually working

with soft aluminum and mild carbon steel makes the job a lot easier when sharp radii have to

be created. In today’s world CAD softwares helps to make the calculations easier.

What Makes Metal Enclosures More Beneficial?

Metal enclosures are in use in the market long before the introduction of plastic enclosures.

Even with plastic enclosures emerging in the market, metal enclosures are more widely

preferred because of their sturdy nature and the height of security they offer for any electric wire

applications. Metal enclosures are resistant to fire, robust, durable and indestructible and these

qualities make them stand out.

Plastic enclosures cannot withstand pressure beyond a certain level and they get twisted.

Plastic enclosures are of more relaxed nature with adequate tension.Hence these plastic

enclosures when given a smash can get twisted and change its shape. This is where metallic

enclosures become beneficial because of their strong and durable nature.

If there is a metal sheathing cable or metal duct going inside or outside the box, use an electric

metal box. Contact is necessary for cables and conduits from metal sheathing to metal boxes.

Choosing the Right Enclosures

Your application and budget will determine which type of enclosure is best for you. The quantity

required and the setting where it is utilized should also be taken into account before determining

the right type of enclosures. One of the top manufacturers of both conventional and customized

metal enclosures are AL Shurooq Industries LLC. We are certified manufacturers with a years

of long standing in the industry.Get in touch with them to find out how we can help, guide and

support your projects.