- About Us

- Products

- Services

- CNC Laser Cutting

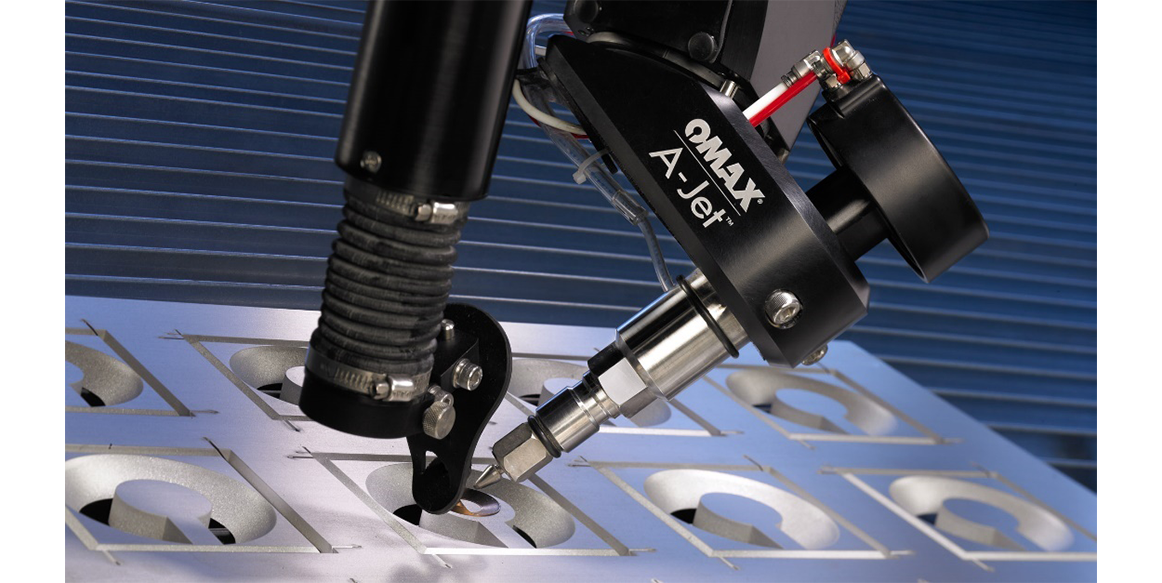

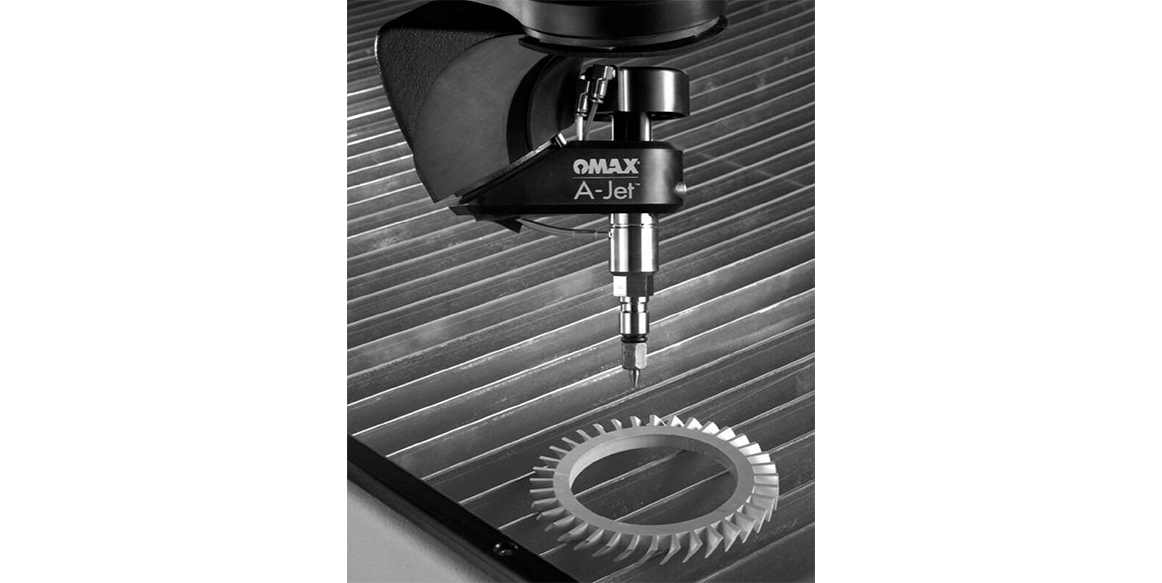

- CNC Water Jet Cutting

- CNC Tube & Pipe Processing

- CNC Plate Processing Center Plasma, Oxy Fuel & Machining

- CNC Turret Punching

- CNC Bending

- CNC Machining

- 5 – Axis CNC Machining

- CAD / CAM & Simulation Services

- Robotic Welding

- Steel Shot Blasting

- Steel Grit Blasting

- Wet Spray Painting

- Powder Coating

- CMM Measurement Services

- Ultrasonic Cleaning Services

- Laser Marking Services

- Prototyping Services

- Resources

- Blogs

- Contact Us

- Request a Quote