"The Importance of Precision Prototypes in Modern Manufacturing"

Preface

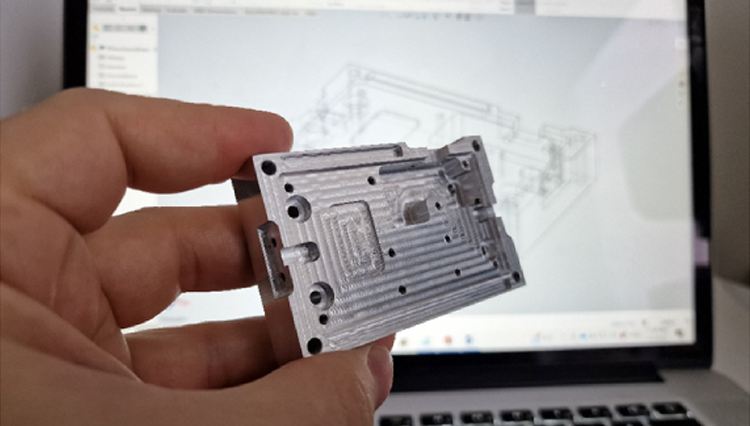

A prototype is a model of a product made to validate the ideas, concept or process used to manufacture

the product. The prototyping process not only involves the manufacturing of the prototype, but also tries

to test the product in real world environments in order to formulate and finalize the design, material of

construction, its form, fit or functions along with the associated risk or failure mode of the process that is

employed to manufacture the product.

Prototyping Process

Depends on the function, criticality and complexity of the product in question, prototyping goes through

several iterations and design of the product before releasing the final design for serial or mass production.

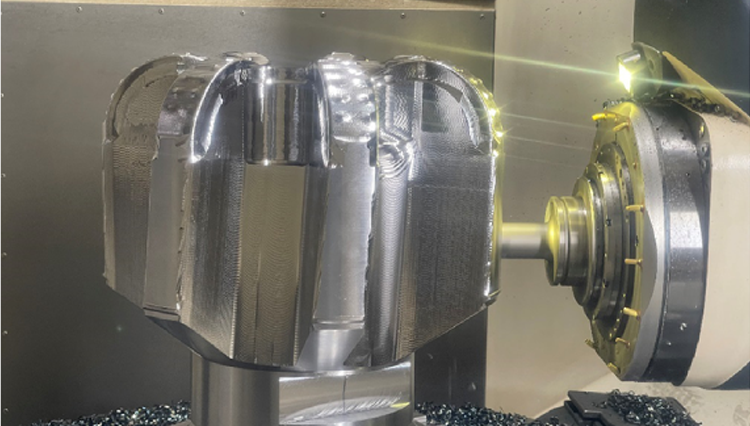

Modern manufacturing techniques such as Laser Cutting, CNC Machining, 3D printing etc. are

increasingly used these days to improve the efficiency of the prototyping process. Rapid prototyping is a

fast growing industry leveraging the advancement of various techniques described above which is

allowing designers and product

The importance of Prototyping Process

Precision prototyping process employed greatly enhances the product life cycle by testing and validating

the actual design before it is released for mass production. Improved design characteristics and

increased quality control inherently available with these modern manufacturing process allows the stake

holders to bring the product to the market and helping them to reduce the errors in design and other

functional requirements.

Latest trends in Prototype Process

Prototyping process has evolved from traditional methods like clay modelling, casting and manual hand

work to advanced manufacturing technologies such as Laser Cutting, CNC Machining, Laser welding, 3D

printing etc. Rapid prototyping is the terms used currently in the industry to reflect this dramatic

advancement in the prototype manufacturing process.

Industries benefiting Precision Prototyping Process

Industries such as Aerospace, Defense, Oil & Gas, Die & Mold, Consumer Goods, Medial Devices and

Automotive Industries significantly leverages the benefits offered by the various precision manufacturing

techniques employed in the rapid prototyping processes. This in turn enabling them to test their parts or

components for its features, functionality, efficiency and safety ensuring performance and customer

requirements.

Summary

Precision prototyping is an integral part of modern manufacturing plants propelling innovation in product

design and improving performance quality of the rapidly changing world dynamics.

At AL SHURROQ, in our state-of-the-art manufacturing plant, we offer prototyping services coupled with

our trademark precision, quality, reliability and our market leading technical support in overcoming the

multitude of challenges faced of our customers.

Visit our website;www.alshurooq.ae for more information about our products or services or get in touch

with us on +971 4 425 5988 to talk to our expert Engineers